In today’s world of smart buildings, data centers, flexible workspaces, and high-tech control rooms, raised floor systems aren’t just a luxury — they’re essential. At Raised Floor NG, we don’t just sell raised floor tiles; we deliver engineered solutions that enhance performance, aesthetics, and efficiency across Nigeria and beyond.

What Is a Raised Floor System — and Why Does It Matter?

A raised access floor (also called an access raised floor) is a flooring structure built above the concrete slab, creating a concealed cavity in between. This hidden space is ideal for routing:

-

Electrical wiring

-

HVAC (heating, ventilation, air conditioning) ducts

-

Data and communication cables

-

Fire suppression systems

-

Plumbing lines

By adopting raised flooring, you unlock benefits like:

-

Neat cable management & flexibility — No messy surface conduits

-

Thermal & air flow control — Use perforated panels or airflow tiles to optimize cooling

-

Ease of retrofits & maintenance — Lift panels to access infrastructure underneath

-

Improved aesthetics & safety — Clean floors without exposed wires

In Nigeria’s growing commercial, telecom, and data center sectors, these advantages are more critical than ever.

Why Choose Raised Floor NG?

When you partner with Raised Floor NG, you’re not just buying tiles — you’re unlocking local expertise, dependable service, and full support. Here’s what sets us apart:

1. Nationwide Delivery & Professional Installation

We deliver raised floor panels and accessories anywhere in Nigeria — from Lagos to Port Harcourt — and our trained technicians ensure clean, fast, and precise installation on site.

2. Direct Distributor = Best Price Guarantee

Because we are a primary distributor, not a middleman, you enjoy more competitive pricing without hidden markups.

3. Diverse Product Range

We offer multiple types of raised floor systems to suit various needs:

-

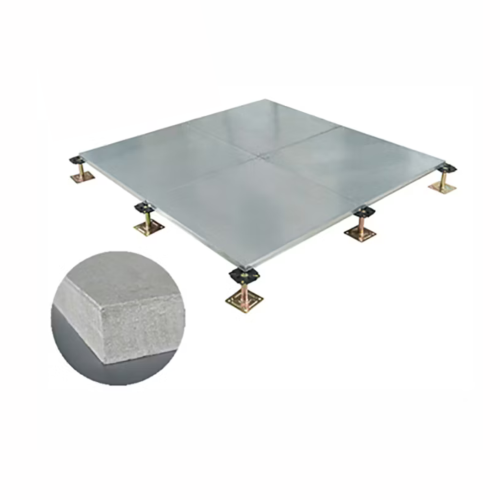

Encapsulated raised floor panels

-

Ceramic-finished raised floors

-

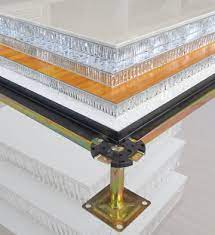

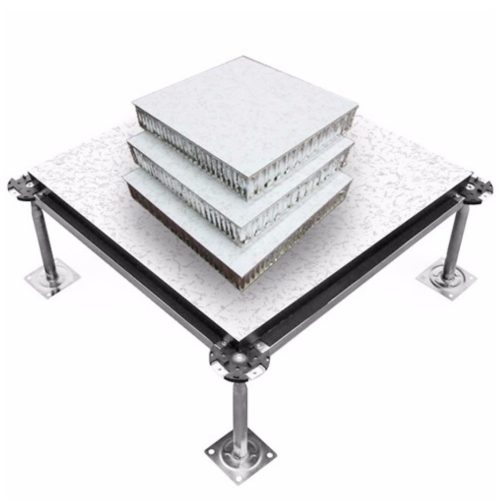

Aluminum honeycomb systems

-

Calcium sulphate panels

-

Cementitious infill steel floors

-

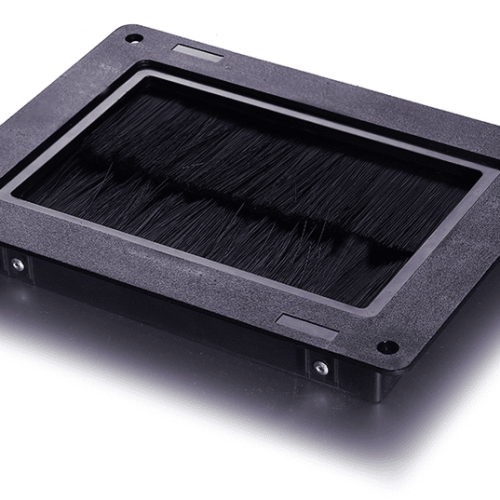

Accessories: pedestals, stringers, brush grommets, adhesives, suction lifters, etc.

4. After-Sales Support & Bulk Discounts

We back your investment with support and incentives — bulk orders qualify for discounts, and we’re ready to help with maintenance or expansion.

Top Use-Cases for Raised Floor Systems in Nigeria

These are some environments where raised floor systems shine:

|

Use-Case |

Benefits |

|---|---|

|

Data Centers & Server Rooms |

Manage dense cable bundling, enable efficient airflow for cooling, and allow flexible rearrangements |

|

Corporate Offices / Call Centers |

Maintain clean aesthetics while allowing reconfiguration of workstations easily |

|

Control Rooms / Command Centers |

Hide cabling in mission-critical environments, ease maintenance |

|

Telecom Exchanges / ISP Facilities |

Support high-density fiber and power wiring while protecting infrastructure |

In each of these settings, the flexibility and infrastructure-hiding ability of an access raised floor system make life easier, safer, and more efficient.

How to Select the Right Raised Floor System for Your Project

To pick an optimal raised floor solution, consider:

-

Load requirements — How much weight (static/dynamic) will the floor carry?

-

Fire safety & compliance — Use fire-rated panels or non-combustible cores

-

Airflow needs — Do you need perforated or ventilated panels?

-

Finish & aesthetics — From ceramic tops to wood-core surfaces

-

Maintenance & access — Panels should be easily removable for servicing

-

Budget & total cost of ownership — Factor in installation, materials, and future upgrades

Our experts at Raised Floor NG can help you perform on-site assessments, run load calculations, and propose the best type of panel system for your environment.

Step-by-Step: Installation Process (What You Can Expect)

To give you transparency, here’s a typical installation workflow:

-

Site preparation — Ensure base slab is level & clean

-

Layout planning — Grid, pedestals, stringers mapped out

-

Pedestal & stringer installation — Fix supports to level reference

-

Panel placement & alignment — Place raised panels; align edges

-

Cutouts & finishing — Vent panels, cable grommets, ceramic or other finishes

-

Testing & inspection — Check flatness, load distribution, serviceability

With well-trained crews, most projects are completed “on time, every time,” as we guarantee.